For almost a century, weathering steel has been used in bridges, fences, buildings, and even artwork. Its unique appearance and ability to avoid corrosion have made it a must-use for many construction and structural projects over the decades.

Even if you haven’t heard of weathering steel, the buildings and structures around your city or hometown have definitely benefited from its use. This article will go over how weathering steel was discovered and come to be as it is today, as well as its practical uses in everyday life.

What is Weathering Steel?

Weathering steel is also referred to as Corten A or Corten B steel. It is an alloy steel that is often used in construction and is well-known for its rust-like appearance.

The outer appearance is actually a protective rust layer called a “patina” that inhibits further corrosion and extends the life and use of the steel. These steels are low alloy and have great strength due to their resistance to corrosion.

The Composition of Weathering Steel

Weathering steel is a low-carbon alloy. The low amount of carbon is what allows it to be tough and ductile. The three alloys in weathering steel are nickel, copper, and chromium.

While weathering steel can rust, it only does so on the outer surface. If the outer coating of rust has grown, the rust does not go further into the steel. The rust-coated surface serves as a kind of protective shield, preventing the steel from any additional corrosion.

The rust layer that is formed on the plain carbon steel is porous and breaks off, which allows it to form another layer deeper into the steel. The cycle continues until the regular steel is useless.

The first layer of rust on the weathering steel forms to hold on because of the contribution of alloys. Hence there is no need to coat the metal with a protective layer as it is self-protected through any sort of weather that occurs. You can, however, coat weathering steel in a protective coating to stop the rust from staining the surrounding areas as the rust will spread when rained on.

The History of Weathering Steel

In the 1930s, the US Steel Corporation developed weathering steel to get the stronger, more durable steel they needed for the hopper carts to carry their ore and coal to the furnace.

Later they realized this metal alloy had useful corrosion resistance that could be marketed and sold in other industries, so the new alloy was trademarked and called COR-TEN® steel.

The first time weathering steel was used for architectural purposes was at the John Deere World Headquarters in Illinois. This building was designed by famed architect Eero Saarinen, and the building was finished in 1964.

Weathering steel is also used for artistic purposes. In 1977, Robert Indiana created a Hebrew version of the LOVE sculpture using weathering steel for the Israel Museum Art Garden in Jerusalem.

Many artists have incorporated weathering steel into their work since its arrival; the most well-known artist being American sculptor Richard Serra. Serra has built numerous, massive sculptures using weathering steel that can be found around the world.

The first weathering steel bridge was a footbridge built in 1967 at York University. It has been used in large bridge and structural applications around the world since. Some examples are the New River Gorge Bridge, the second span of the Newburgh–Beacon Bridge in 1980, and the Australian Center for Contemporary Art (ACCA) and MONA.

It was also used in 1971 for the Highliner electric cars built by the St. Louis Car Company for the Illinois Central Railroad. Using weathering steel was seen as a way to cut costs in comparison with the pricey stainless steel that was the railcar standard.

Companies such as MetalTech Global have vast experience in fabrication and artful design, which can be seen in such projects like:

- Embry Riddle Aeronautical University in Florida

- CREC Academy of Aerospace & Engineering in Connecticut

- Los Angeles Trade Technical College in California

- Owensboro Convention Center in Kentucky

- Casa Val in Costa Rica

- Chelsea Studios in New York

These examples show the range of what perforated metal can do in the hands of experts and talented artists and craftspeople.

How Long Does Weathering Steel Last?

Because of its protective rust coat that provides corrosion resistance, weathering steel used in bridges, architecture, and other mediums can last upwards of a few decades to over 100 years in the proper conditions.

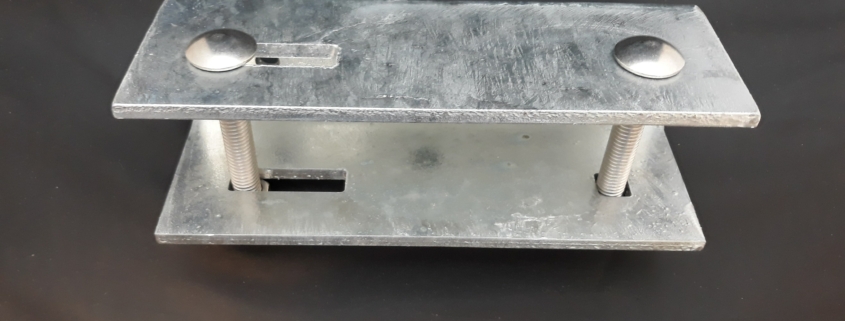

Get Quality Materials for Your Next Project

MetalTech Global is the nation’s premier distributor and fabricator of coil, sheet, and finished architectural metals products. We promote the use of sustainable metal products in the buildings and are able to create custom perforated patterns and shapes as well. With high-tech tools and over 25 years of experience, our architectural support staff can realize an unlimited variety of folded and perforated panel designs.

Contact us today for all of your weathering steel, perforated metal, coil, panel, and fabrication needs! We hope to work with you today to realize your next architectural dream.